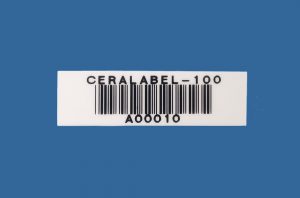

SIGMAX’s barcode labels deliver reliable readability even under the most demanding conditions.

Through proprietary technologies such as the CERALABEL series, we provide exceptional performance in heat resistance, chemical resistance, impact resistance, and more.

Proven by years of data and field testing, these advanced features ensure durability and reliability across every production environment.

Specifications

| Performance / Product Name | CERALABEL 100 |

CERALABEL 200 |

CERALABEL 300 |

CERALABEL SL-600 |

CERALABEL SL-800 |

CERALABEL SL-1000 |

CERALABEL TF |

Aluminum label | Etched label | US C |

US E |

US-G |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat Resistance (Maximum Operating Temperature) | 800℃ | 1100℃ | 1400℃ | 600℃ | 800℃ | 1000℃ | 200℃ | 300℃ | 300℃ | 1700℃ | 1100℃ (Oxidizing and Reducing Atmosphere) | 2500℃ (Reducing Atmosphere) |

| Water Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| Solvent Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| Oil Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| Acid and Alkali Resistance | 〇 | ◎ | ◎ | 〇 | 〇 | 〇 | ◎ | ✕ | 〇 | ◎ | 〇 | - |

| High-Temperature Alkali Resistance | △ | 〇 | 〇 | △ | △ | △ | ◎ | ✕ | ◎ | 〇 | ◎ | - |

| Hydrofluoric Acid Resistance | ✕ | ✕ | ✕ | ✕ | ✕ | ✕ | ◎ | ✕ | ✕ | ✕ | ✕ | - |

| Dirt Resistanc | △ | △ | △ | 〇 | 〇 | 〇 | ◎ | 〇 | △ | △ | 〇 | 〇 |

| Impact Resistance | △ | △ | △ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | △ | ◎ | ✕ |

| Flexural Resistance | ✕ | ✕ | ✕ | ◎ | ◎ | ◎ | △ | ◎ | ◎ | ✕ | 〇 | ✕ |

| Small Labels | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ✕ | ◎ | ◎ | △ | 〇 | △ |

| Large Labels | △ | △ | △ | ◎ | ◎ | ◎ | △ | ◎ | ◎ | △ | ◎ | △ |

Specifications

| Performance / Product Name | CERALABEL 100 |

CERALABEL 200 |

CERALABEL 300 |

CERALABEL SL-600 |

CERALABEL SL-800 |

CERALABEL SL-1000 |

CERALABEL TF |

Aluminum label | Etched label | US C |

US E |

US-G | Performance / Product Name |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat Resistance (Maximum Operating Temperature) | 800℃ | 1100℃ | 1400℃ | 600℃ | 800℃ | 1000℃ | 200℃ | 300℃ | 300℃ | 1700℃ | 1100℃ (Oxidizing and Reducing Atmosphere) | 2500℃ (Reducing Atmosphere) |

Heat Resistance (Maximum Operating Temperature) |

| Water Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | Water Resistance |

| Solvent Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | Solvent Resistance |

| Oil Resistance | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | Oil Resistance |

| Acid and Alkali Resistance | 〇 | ◎ | ◎ | 〇 | 〇 | 〇 | ◎ | ✕ | 〇 | ◎ | 〇 | - | Acid and Alkali Resistance |

| High-Temperature Alkali Resistance | △ | 〇 | 〇 | △ | △ | △ | ◎ | ✕ | ◎ | 〇 | ◎ | - | High-Temperature Alkali Resistance |

| Hydrofluoric Acid Resistance | ✕ | ✕ | ✕ | ✕ | ✕ | ✕ | ◎ | ✕ | ✕ | ✕ | ✕ | - | Hydrofluoric Acid Resistance |

| Dirt Resistanc | △ | △ | △ | 〇 | 〇 | 〇 | ◎ | 〇 | △ | △ | 〇 | 〇 | Dirt Resistanc |

| Impact Resistance | △ | △ | △ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | △ | ◎ | ✕ | Impact Resistance |

| Flexural Resistance | ✕ | ✕ | ✕ | ◎ | ◎ | ◎ | △ | ◎ | ◎ | ✕ | 〇 | ✕ | Flexural Resistance |

| Small Labels | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ✕ | ◎ | ◎ | △ | 〇 | △ | Small Labels |

| Large Labels | △ | △ | △ | ◎ | ◎ | ◎ | △ | ◎ | ◎ | △ | ◎ | △ | Large Labels |

CERALABEL LSL is the on-site marking ceramic barcode label can be used under the production conditions such as fiercely high temperature and abrasive chemicals.

―CERALABEL ®LSL -

Heat Resistance Test Video

Heat resistance

Suitable for long-term heat treatment and firing processes at 400 to 1,650°C. (Partly compatible with 2,500°C under reducing atmosphere)Main application

・Long-term heat treatment process for special steel wire rods and coils

・Heat treatment process for semiconductors, glass substrates, etc.

・Firing process for sanitary ware and ceramics

・Carburizing process for automobile parts, etc.

Products

Chemical resistance

It is effective in chemical treatment processes involving common organic solvents such as alcohol and acetone, as well as oils, acids, alkalis, and various cleaning fluids.

Main application

・ Wet etching process for solar cells

・Hydrofluoric acid cleaning and ultrasonic cleaning processes for semiconductor wafer cases, metal products, medical equipment, glass products, etc.

・High-temperature alkali treatment process for tempered glass, etc.

Products

Weatherability

Even in an outdoor environment exposed to sunlight, wind and rain, it does not lose its functionality as a long-term nameplate for management.

Main application

・As a management nameplate for cargo ship containers

・Management of containers that exchange parts between warehouses and factories

・Beer casks, etc.

Products

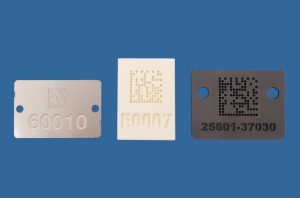

Shock resistance

Suitable for managing parts and members that require physical strength.

Main application

・Unique identification labels for train parts, automobile parts, etc. that are subjected to a certain amount of mechanical shock, etc.

Products

Woven fabric barcode labels

Woven fabric labels with barcode or/and 2D code woven by polyester yarn. Polyester threads of various colors can be used, making it possible to identify items by color.

Main application

・Management of uniforms and work clothes, process management in cleaning

・Management of various clothing and linens for medical facilities and hospitals

・Luxury costume rental for wedding halls, costume management for theme parks, etc.

Pruducts

On-site printable barcode labels

Heat-resistant and chemical-resistant barcode labels for various manufacturing sites, such as the type that attaches an unfired ceramic label to the product before the heat treatment process, is fired and welded, and the type that is issued using a special ceramic label for ceramics and sanitary ware, and a laser marker.

Main application

・Management of lens mold

・Firing process for ceramics and sanitary ware

・Vehicle and aircraft parts management nameplates, etc.

Products

Processing

Our special barcode labels can be customized in a wide variety of ways depending on the usage environment and mounting conditions. From size, shape, and color differentiation to bending and drilling for specific implementations, we deliver the most suitable labels tailored to the challenges of each site.

Size & Shape

Color

Bending & Drilling

We have a proven track record of producing barcode labels as small as 1.7 mm on the short side. From ultra-compact sizes to a wide range of shapes and dimensions, we can manufacture labels that best match the application and surface, including square, rectangular, circular, or with rounded corners.

For stainless steel and aluminum labels, bending can be applied to match the shape of the mounting surface. We also support drilling for screw-fastening, enabling secure attachment even in harsh environments.

Beyond barcodes, our labels support 2D codes such as QR codes and Data Matrix, as well as serial number management. These special barcode solutions adapt to any environment, ensuring reliable traceability and supporting digital transformation (DX).